QI-R-M12 universal pneumatic tapping machine

Floating pneumatic tapping machine, also known as universal tapping machine, pneumatic tapping machine for short, is a high-efficiency pneumatic tool mainly used for cutting threads, chamfering, screwing, etc.

Product description

The pneumatic tapping machine is equipped with a mechanical arm that can move up and down, back and forth, left and right, and has a large working radius, breaking through the space limitations of traditional equipment such as lathes, drilling machines, and boring machines. When cutting the thread, it is guided by the tap, and is always kept perpendicular to the working surface, without tension and pressure, and in a floating state, thus ensuring the precise geometric size of the thread. When used in conjunction with a mobile worktable, it has unparalleled advantages in thread cutting for large workpieces, complex workpieces, and multi-hole workpieces: flexible maneuverability, fast repeat positioning, and high precision.

Working principle

When the high-pressure air enters the tapping machine motor through the air pressure regulator, press the trigger, the high-pressure air enters the motor through the intake valve and the reversing button assembly, and drives the rotor blades of the motor to generate circumferential rotational force. After the rotor moves, it passes through each gear pair. The variable speed outputs a strong torque, which drives the tap to perform the tapping operation. The working air pressure of the tapping machine can be determined according to the size of the tap and the material of the product. Therefore, please select the deceleration mechanism correctly according to the size of the tap and the material of the product.

Scope of application

What should I do if the workpiece material cannot be penetrated due to special attack? Blind holes are not easy to attack? Are the taps slippery or prone to breakage? Poor chip evacuation and unsatisfactory thread accuracy? Too many holes to tap? The workpiece is too large and there are too many faces to attack? Is manual tapping too expensive? All problems can be solved by pneumatic tapping machine.

Features of Pneumatic Tapping Machine

1. As a companion of CNC equipment, it becomes its auxiliary workbench. Make the operator's waiting time more productive, free the CNC from tedious work such as "tapping" and "chamfering", and greatly improve the efficiency of CNC and operators.

2. The ergonomic design is easy to operate, comfortable and reduces fatigue.

3. When working, no tension and pressure are generated, the operation is free and flexible, and the balance is accurate and in place.

4. The operation is simple and light, no experience and strength are required at all, and the operator does not need special training. With a little training, the operator can operate lightly and precisely, move flexibly, repeat positioning quickly, have high precision, and have a large working range.

5. Compressed air drive, safe, fast and efficient.

6. Small air pressure and air volume, large torque output.

7. Wide range of applications, capable of tapping various steel, iron, copper, aluminum, plastic and other materials.

8. The speed of the motor can be adjusted indefinitely, and the barrel is equipped with an overload protection device, so the tapping damage is small, the screw thread precision is high, and the overload operation will not damage the motor.

9. Heavier workpieces do not need to be positioned or flipped, and can be easily fixed by adding a universal head.

Applicable industries

Machinery, molds, electronics, metallurgy, power plants, coal mines, petroleum

Standard content

Frame, air motor, A230 reducer, accessory box, tapping oil, tap chuck M5A, M8A, M10A, M12A 1 each

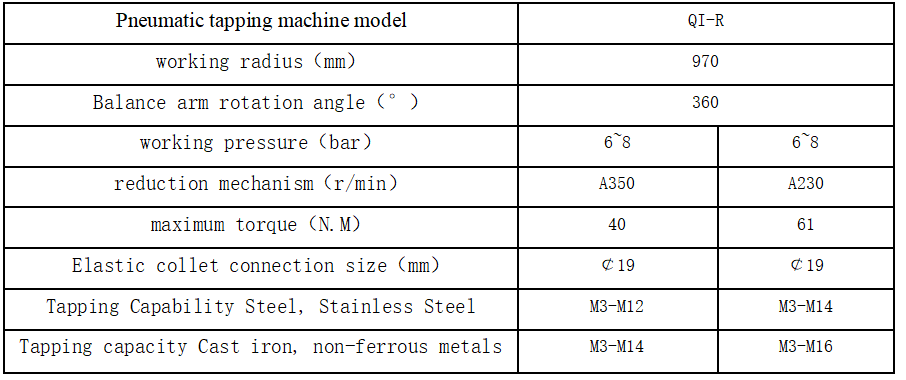

Specification

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: ella.cai

Phone: 008615022633418

E-mail: aihua_1981@163.com

Whatsapp:008615022633418

Add: Wangchuanchang road 1#,Hedong District,Tianjin City,China