News

Do you know what should be paid attention to when selecting the oil pump model?

Do you know what should be paid attention to when selecting the oil pump model?

The selection of oil pump model shall be based on the production process and system requirements, taking into account the five aspects of liquid characteristics, liquid gas supply, equipment working pressure, pipeline layout and actual operation standards.

1. Liquid properties include the name of liquid substance, chemical properties, physical properties and other properties. Chemical properties include temperature, relative density, viscosity, diameter of solid particles in the substance, composition of vapor, etc. This involves the working pressure of system software, measurement of required driving force, and types of suitable pumps: physical properties, key refers to organic chemical corrosion and toxic side effects of liquid substances, It is an important link to adopt the raw materials of oil pump and the sealing form of water pump.

2. The total flow is one of the key characteristic data information of the optional oil pump, which is immediately related to the production and transportation capacity of all system software equipment. When selecting cycloidal gear pump, the larger total flow is taken as the basis, and all normal total flows are included. When there is no larger total flow, 1.1 times of all normal total flows can generally be used as the larger total flow. In the production process of general industrial pumps, the leakage in the pipeline system software can be ignored, but the harm to the total flow when the processing process changes must be considered.

3. The working pressure required by the equipment system software is another key characteristic data information for selecting the transmission gear oil pump. Generally, the model and specification of cycloidal gear pump shall be selected by using the working pressure after increasing the capacity by 5% - 10%. This includes: working pressure of oil suction pool, working pressure of oil discharge pool, gas pressure in pipeline system software (working pressure damage).

4. The pipeline layout standard of oil pump equipment system software refers to the height width ratio, spacing and direction of liquid delivery. It is convenient to check the driving force strength of system software working pressure measurement. If necessary, equipment characteristic curve diagram shall be made for pipeline system software data information. When designing the pipeline layout in the scheme, the following matters should be paid attention to: A. Effectively select the pipe diameter. The pipe diameter is large. Under the same total flow rate, the flow rate is small, and the friction resistance damage is small. However, the high price and small pipe diameter will cause the friction resistance damage to expand significantly, which will increase the working pressure of the selected pump, increase the wear output power, and increase the cost and operating cost. Therefore, it should be comprehensively considered from the perspective of technology and economic development. B. The discharge side of the pump must be equipped with gate valve and check valve. The gate valve is used to adjust the working condition point of the pump, and the check valve can prevent the oil pump from overturning when the liquid is in reverse flow. C. The pipeline layout shall be arranged as connecting pipes as far as possible, and the notes in the pipeline shall be reduced as far as possible and the length of the pipeline shall be reduced as far as possible. When it is necessary to turn, the bending radius of the elbow shall be 3~5 times of the pipe diameter, and the viewing angle shall be more than 90 ℃ as far as possible. D. The discharge pipe and tee joint shall take into account the large working pressure they can bear.

5. There are many standards for the actual operation of the oil pump, such as the working temperature of the liquid, the suction pressure, the working pressure of the outlet side vessels, the average altitude, the working temperature, whether the actual operation is intermittent or continuous, and whether the gear oil pump is fixed or movable.

6. The installation of the oil pump shows that: 1. The advantages and disadvantages of the pump installation are very important to the stable operation and service life of the pump. Therefore, the installation work must be carried out carefully and should not be done hastily. 2. The installation height width ratio, length and pipe diameter of the pump suction pipe shall take into account the measured values to ensure simplicity and reduce unnecessary damage (such as elbows); And ensure that the allowable NPSH is not exceeded when the pump is working. 3. The suction and discharge pipes shall have supports. The pump is not allowed to bear the load of the pipeline. 4. The location where the pump is installed should be wide enough to facilitate maintenance work.

7. Installation sequence: 1. Place the generator set on the base with embedded anchor screws, and use double wedge pads between the base and the base. 2. Loosen the coupling, put the level gauge on the pump shaft and the base respectively, adjust the wedge pad according to the standard of the generator set, and tighten the anchor screws appropriately to prevent walking. 3. Correct the coaxiality of the pump shaft and motor shaft, and the allowable error is 0.1mm on the outer circle of the coupling; The clearance in the plan of two couplings shall be 2~4mm, and the clearance (small value for small pump) shall be even, with an error of 0.3mm. 4. After connecting the pipe and determining the rotation direction of the motor, connect the coupling and check the coaxiality of the shaft again. 5. The final inspection shall be carried out 2~3 hours after the specific test run of the generator unit. If there is no potential safety hazard, the installation shall be deemed as up to standard. Check the temperature and vibration of rolling bearing during the whole process of test run. 6. During the whole installation process, all holes of the generator set shall be covered to avoid dirt falling into the equipment. 7. In order to prevent dirt in the pipeline from entering the pump, a filter device shall be installed at the oil outlet of the pump for newly installed pipeline, and its reasonable cross section shall be 2-3 times greater than that of the suction inlet.

RELATED NEWS

- The principle of ball screw transmission: 2022-01-06

- Do you know the correct operation method for installing ball screw nut pair? 2022-01-06

- How to distinguish between good quality and bad linear guide rail 2021-10-16

- Hiwin linear guides promote the rapid development of automation technology 2021-10-16

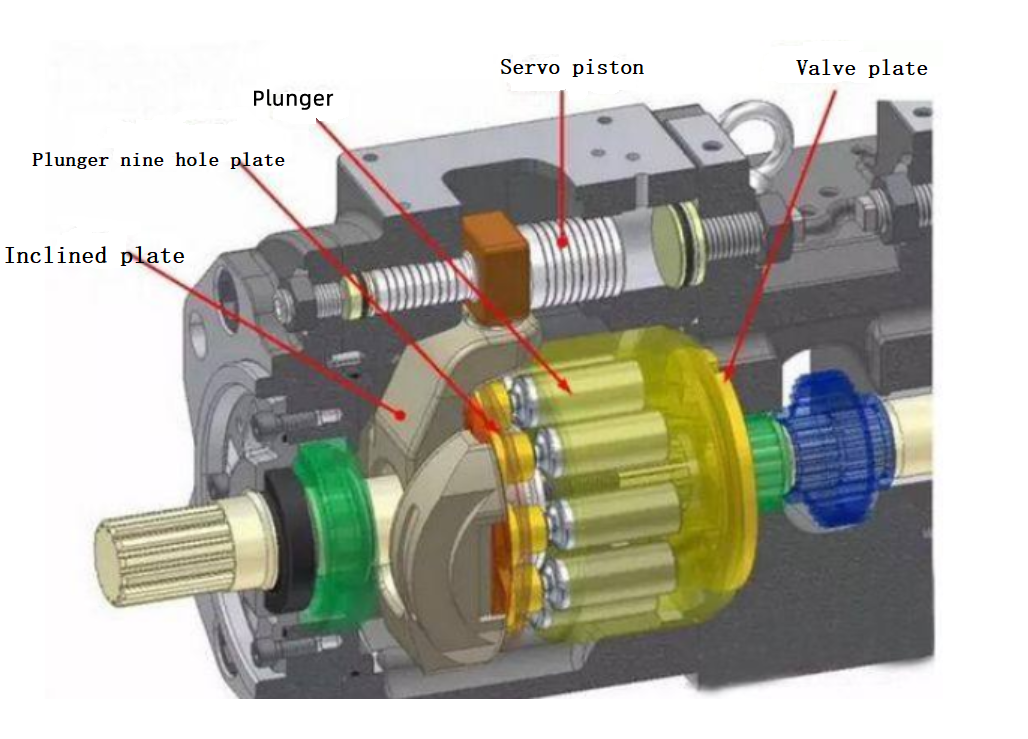

- Structure and working principle of plunger pump 2022-11-03

CATEGORIES

LATEST NEWS

CONTACT US

Contact: ella.cai

Phone: 008615022633418

E-mail: aihua_1981@163.com

Whatsapp:008615022633418

Add: Wangchuanchang road 1#,Hedong District,Tianjin City,China