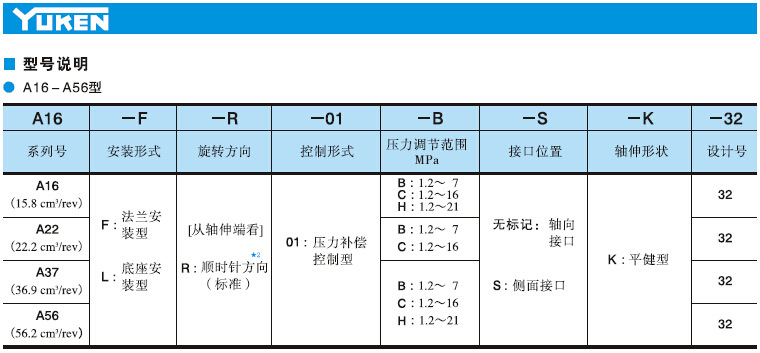

A56-F-R-01-H-K-32 YUKEN Plunger Pump

A56-F-R-01-H-K-32 YUKEN Plunger Pump

A56-F-R-01-H-K-32 YUKEN Plunger pump

1. A series hydraulic fluid of variable displacement piston pump: petroleum based hydraulic oil, anti-wear hydraulic oil or R or O (anti rust and anti-oxidation) hydraulic oil (ISO VG2 or 46) can be used. When the temperature is 0~60 ℃, the viscosity of the oil is 20~400cSt.

2. A series pollution control of variable displacement piston pump: pay attention to the oil pollution control, otherwise the components will be damaged and their life will be shortened. To keep the pollution level within NAS10, the oil suction port must be installed with an oil filter of at least 100 ü m (150 meshes). An oil filter of less than 10 ü m must be installed in the oil return circuit.

3. Installation of variable piston pump A series: the oil filler shall be upward, and rubber shockproof pad shall be added as much as possible during installation.

4. Alignment of A-series shaft of variable displacement piston pump: use flexible coupling as far as possible to avoid any stress caused by bending or thrust. The error of different axes shall be less than 0.25mm (0.01in), and the angle error shall be less than 0.2 °.

5. Suction pressure of variable piston pump A series: the allowable suction pressure is between -0.16 -+0.5bar, the diameter of suction inlet piping is the same as that of all specified pipe flanges, the suction inlet of variable piston pump is higher than the oil tank level, and the height must be less than 1m.

6. Instructions for A series piping of variable plunger pump: all oil pipes connected to variable plunger pump shall be hoses.

7. A series suction pipe of variable displacement plunger pump: if the variable displacement plunger pump is installed above the liquid level, the suction pipe and the suction pipe oil filter should be lower than the installation position of the variable displacement plunger pump to prevent air from entering the suction pipe. Since the hydraulic oil in the suction pipe of the variable displacement piston pump starts to run from the stop when the flow is 0, it is easy to generate negative pressure. The suction pipe should adopt the dimensions in Table 1 and be as short as possible.

8. A series oil drain pipe of variable piston pump: during installation, ensure that the pressure in the cavity of the variable piston pump is kept below 1 bar (1 kgf/cm2), the normal pressure, and the impact pressure is less than 5 bar. The pipe length shall be less than 1m, the pipe end shall be immersed in oil, and the drain pipe shall be connected to the oil tank separately.

10. Start of variable displacement piston pump A series: before the first start, fill the variable displacement piston pump chamber with clean working fluid through the filler port. To avoid air blockage during the first start, adjust the control valve to make the oil output from the variable piston pump directly return to the oil tank, or make the actuator move under no-load condition.

11. Noise and vibration control of A series hydraulic system of variable displacement piston pump: its pulse waveform is different from that of vane pump, so the noise is affected by the rigidity, installation and piping of the host, which may increase the noise. Therefore, attention should be paid to the installation of variable displacement piston pump.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: ella.cai

Phone: 008615022633418

E-mail: aihua_1981@163.com

Whatsapp:008615022633418

Add: Wangchuanchang road 1#,Hedong District,Tianjin City,China