Pneumatic motor of tapping machine

Pneumatic motor of tapping machine

Pneumatic motor of tapping machine

The pneumatic motor of Leda special tapping machine has the advantages of large torque, long service life, long maintenance free cycle and not easy to be damaged.

1. The torque is large. At the beginning of the design, the working form and working capacity of the hydraulic motor of Hairui special tapping machine were considered, which increased the power.

2. The service life is long. The traditional pneumatic motor is researched by Hairuite tapping machine, which has a short service life and is easy to be damaged. The rotor of the traditional pneumatic motor is made of powder metallurgy material, which is not wear resistant. Hairuite has systematically upgraded its service life to about 10 years, and the maintenance free cycle is more than 5 years.

The pneumatic motor device produced by Hairui Special Tapping Machine is equipped with a speed change system, which is driven by the spindle of the specially designed filtered and lubricated compressed air driven motor, and works together with the tap installed in the floating chuck of the motor speed change system.

When the high-pressure air enters the tapping machine motor through the air pressure regulator, press the trigger, and the high-pressure air enters the motor through the air inlet valve and the reversing button assembly to drive the motor rotor blades to generate a circumferential rotation force. After the rotor moves, the powerful torque is output through the gear pairs to drive the tap for tapping. The working air pressure of the tapping machine can be determined according to the tap size and product materials, so please correctly select the reducer for use according to the tap size and product materials.

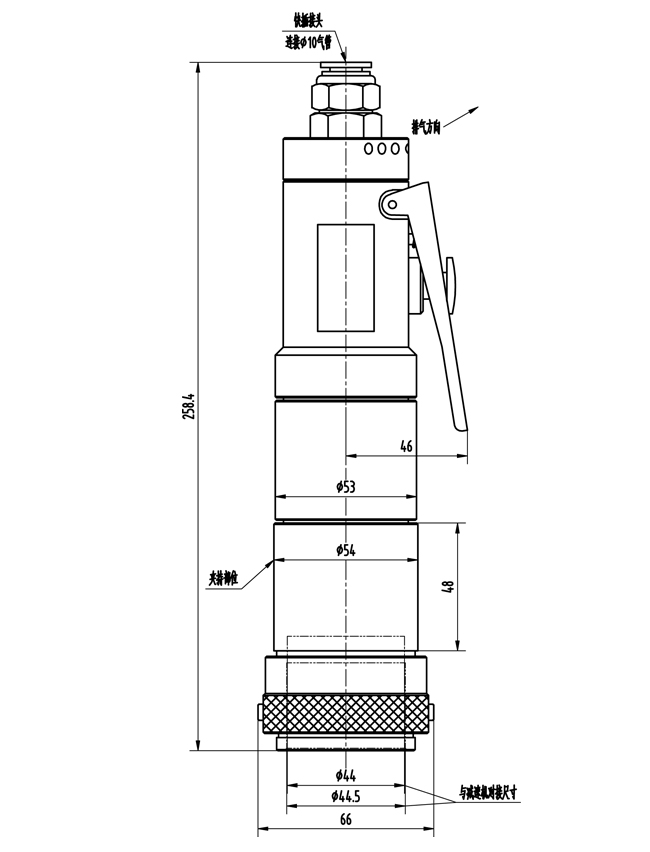

Outline dimension drawing of motor

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: ella.cai

Phone: 008615022633418

E-mail: aihua_1981@163.com

Whatsapp:008615022633418

Add: Wangchuanchang road 1#,Hedong District,Tianjin City,China